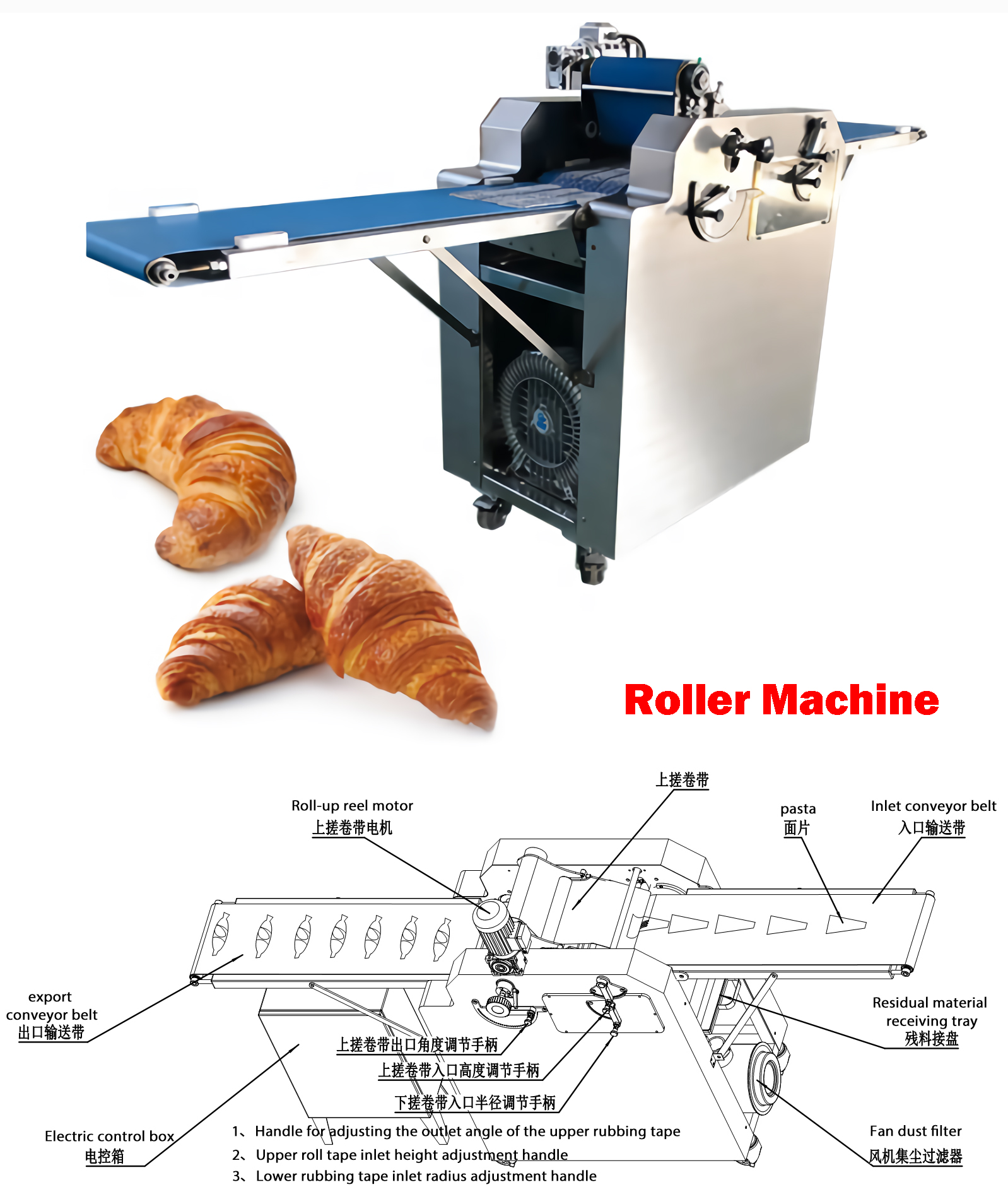

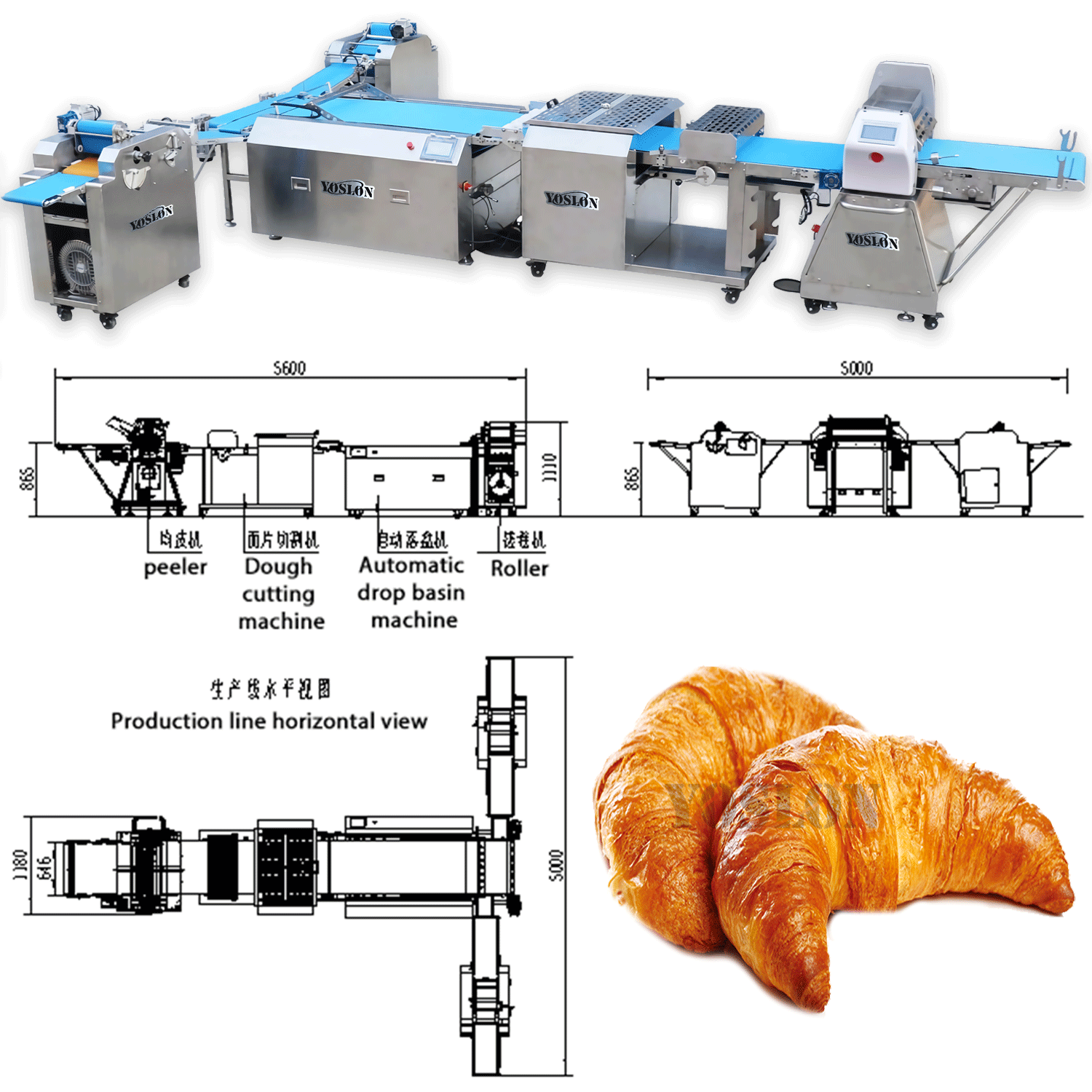

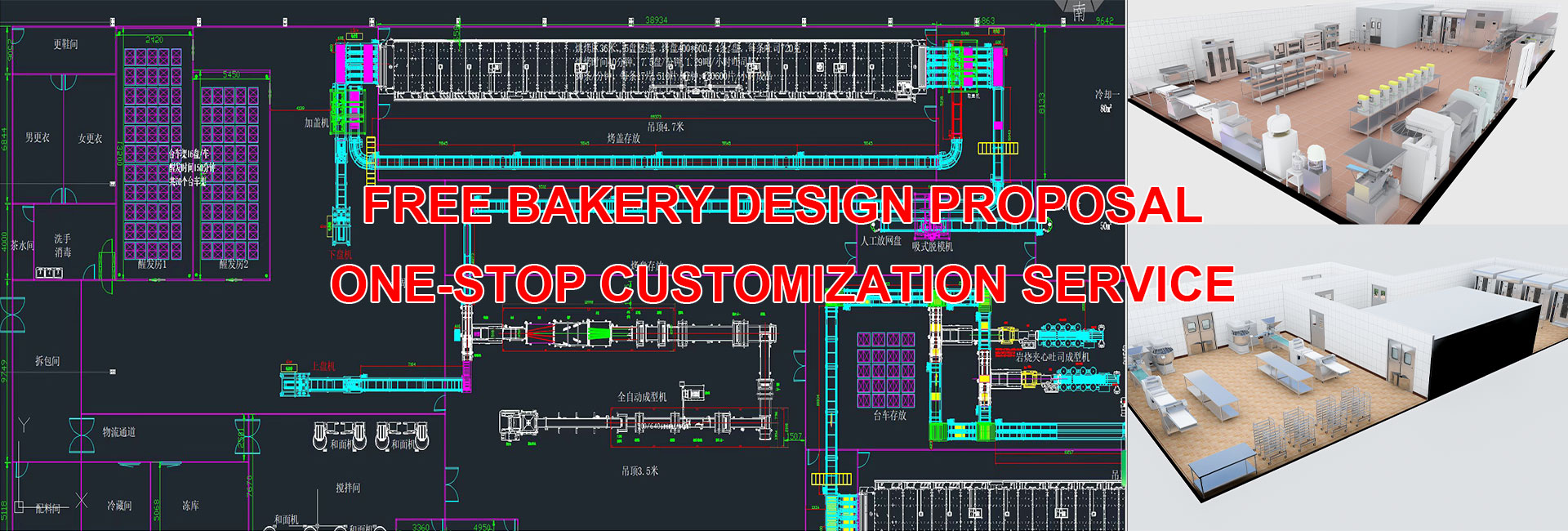

Yoslon Fully Automated Croissant Production Line Bakery Dough Croissants Rolling Bread Baking Equipment Cutting Machine Line

-

Product Description

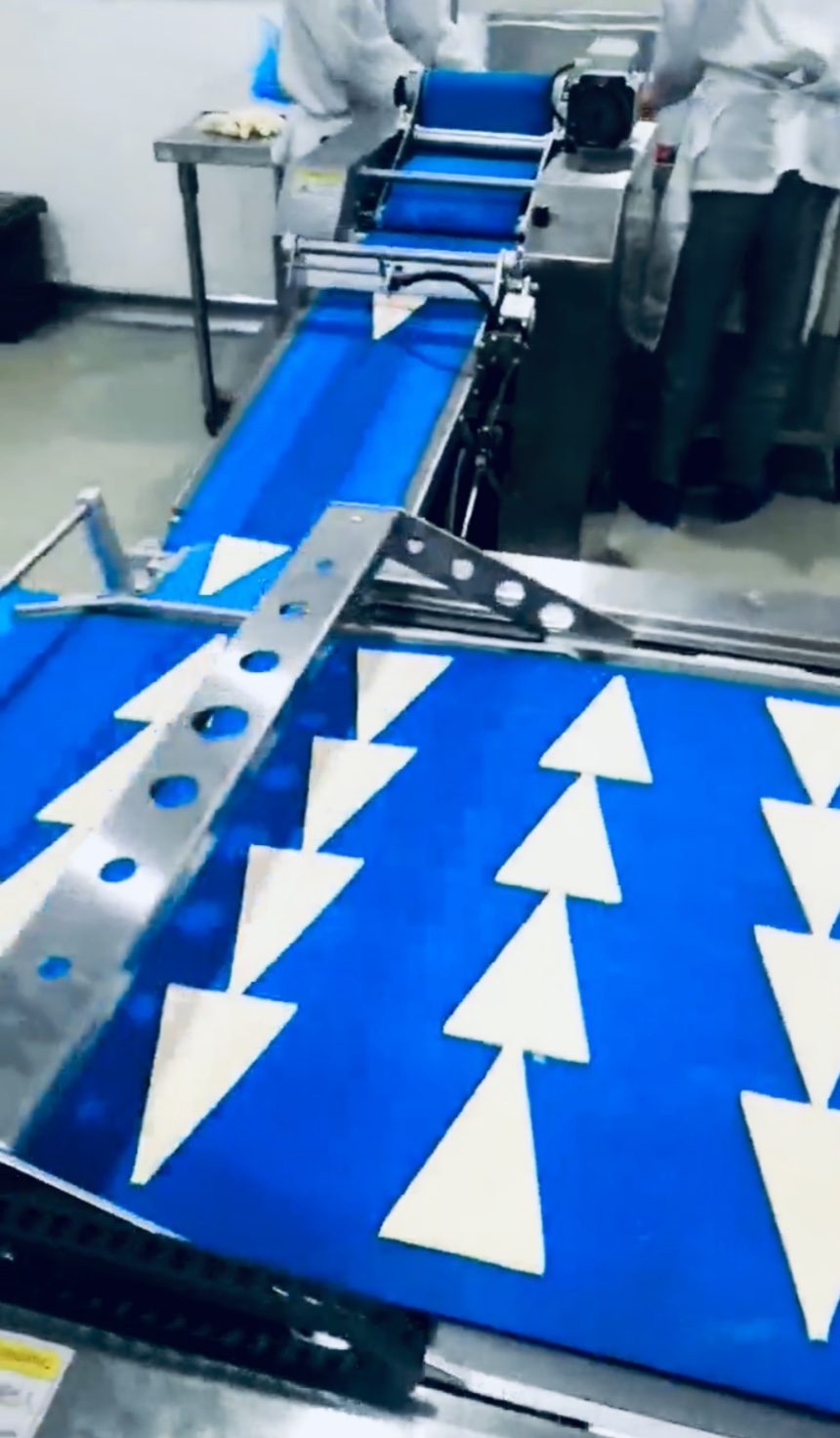

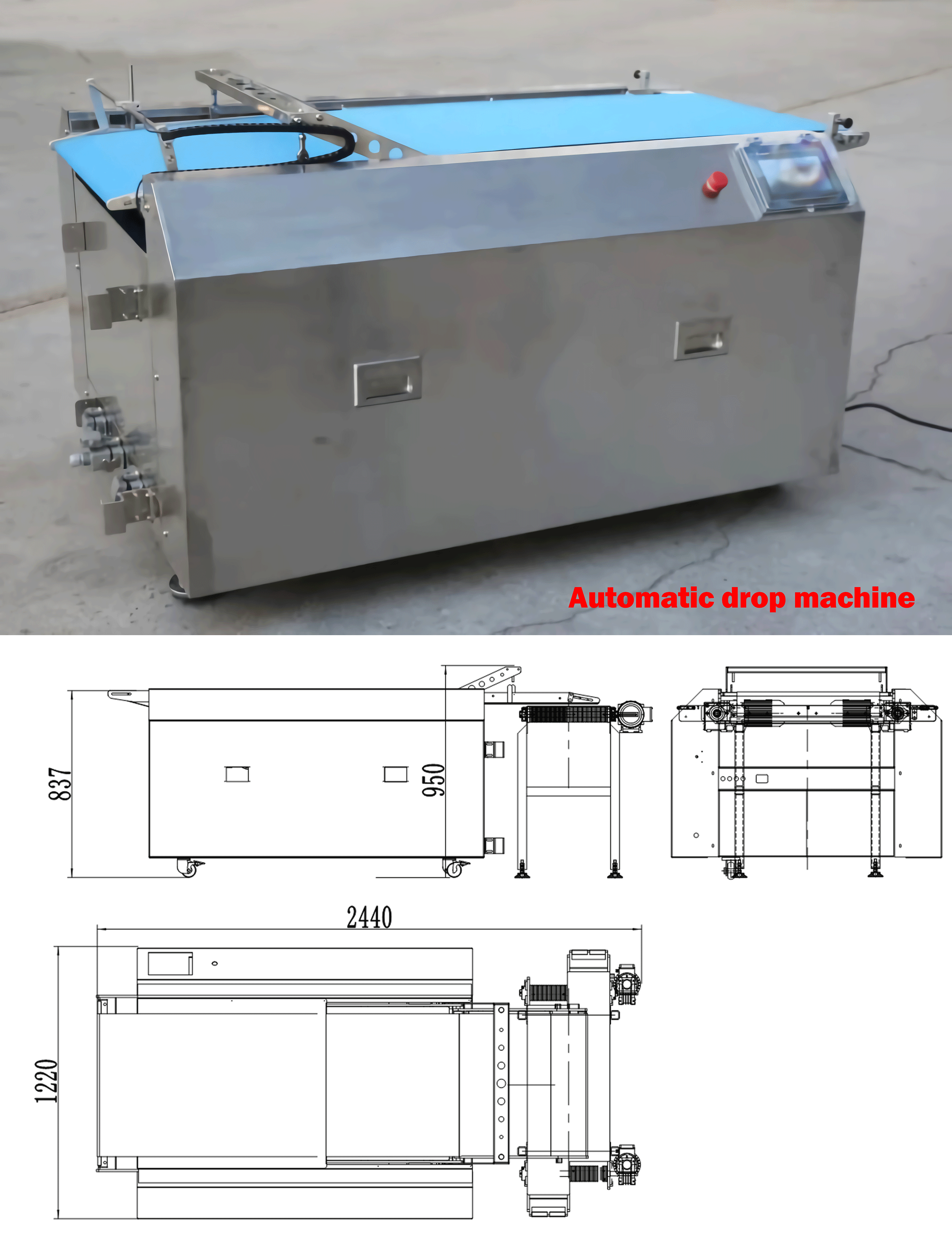

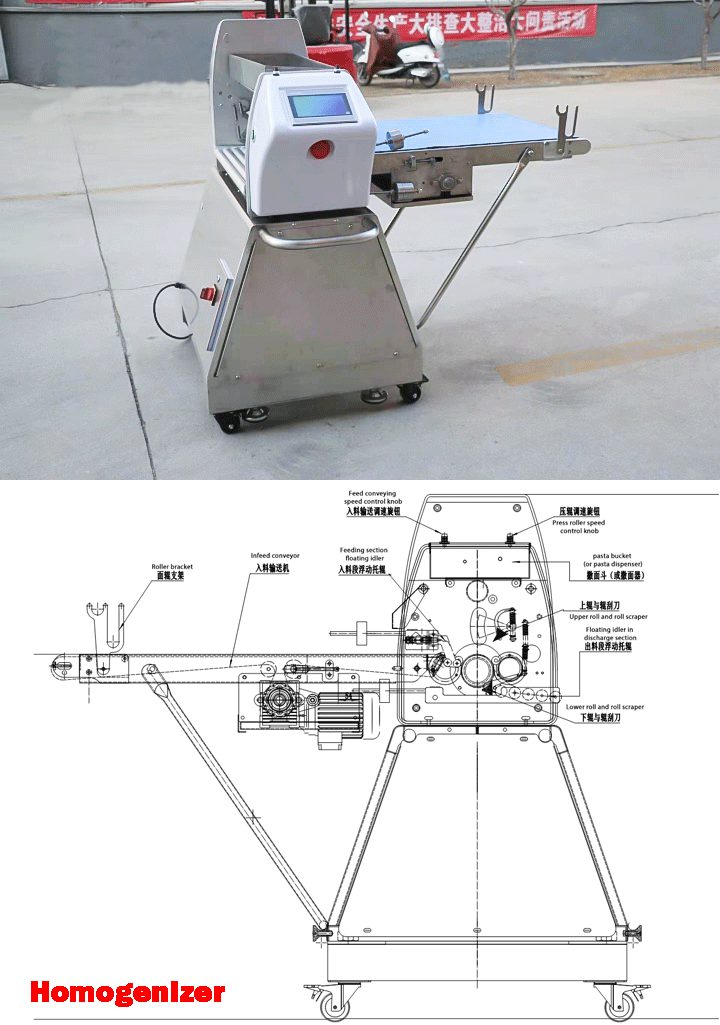

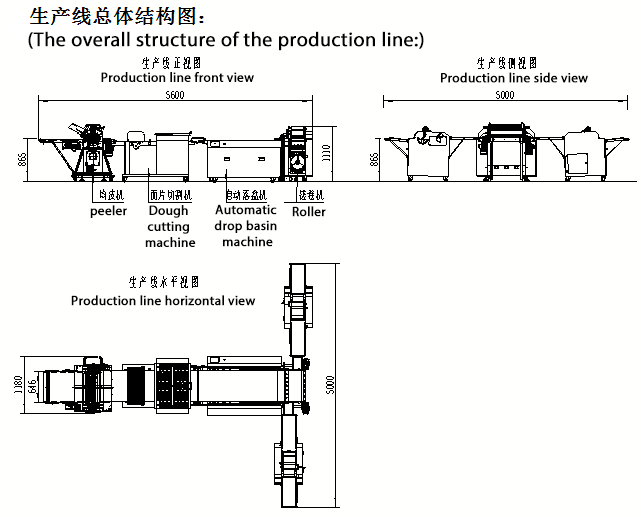

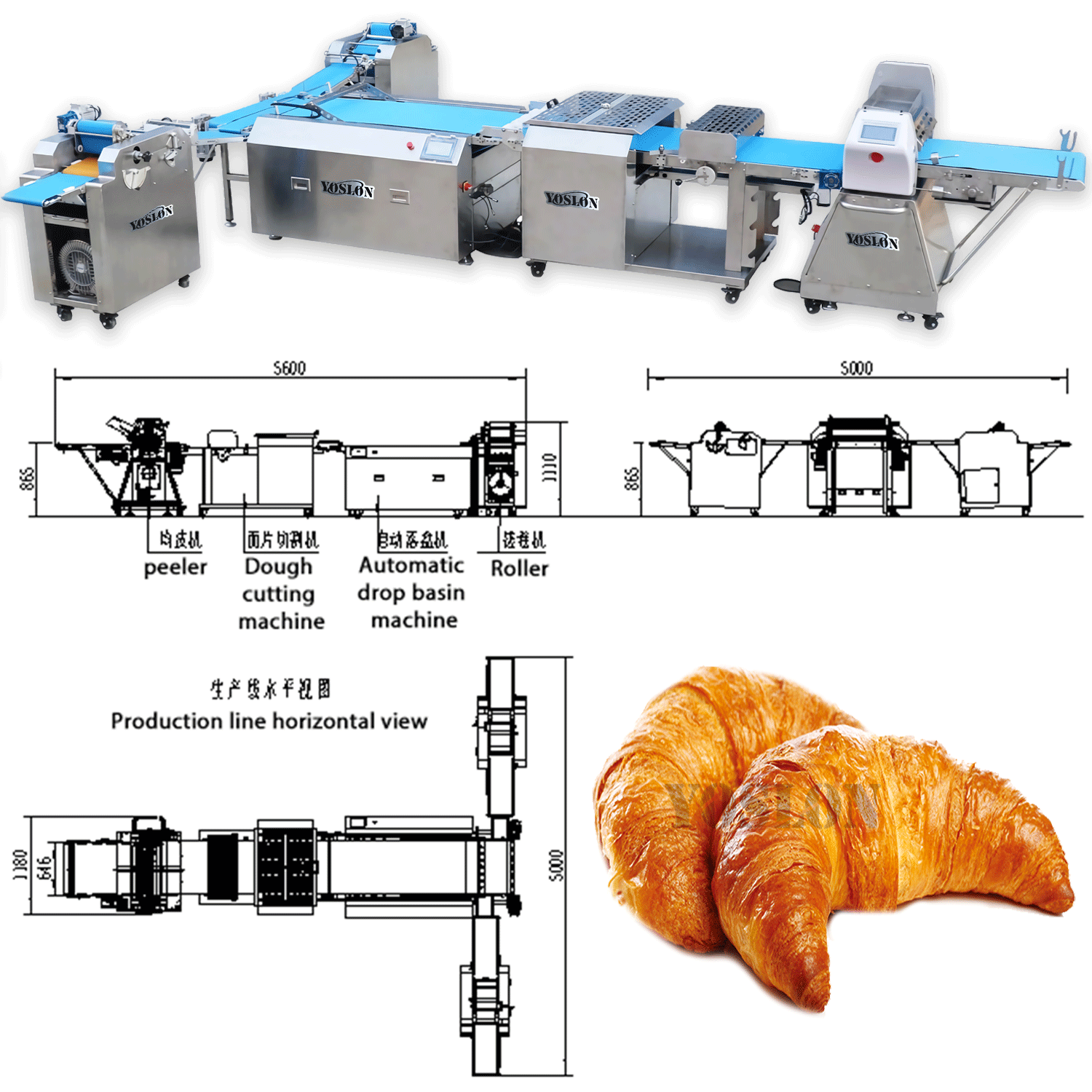

The horn forming line is a complete set of bidirectional horn rolling equipment. The production line includes a skin homogenizer, a dough slicer, an automatic plate dropper, a directional conveyor, and a single-row rolling machine. This production line does not include a crisper, and a fully automatic crisper can be selected if required.

The production line has high production efficiency, and the rolling yield can reach 98%. The output of large horns is about 5000-6000 per hour, and the output of calf horns can reach 8000-10000 per hour. The unit is compact in structure and occupies a small area. The minimum area is only 5.6 meters * 5 meters. It is very suitable for small and medium-sized food factories with small plant area.

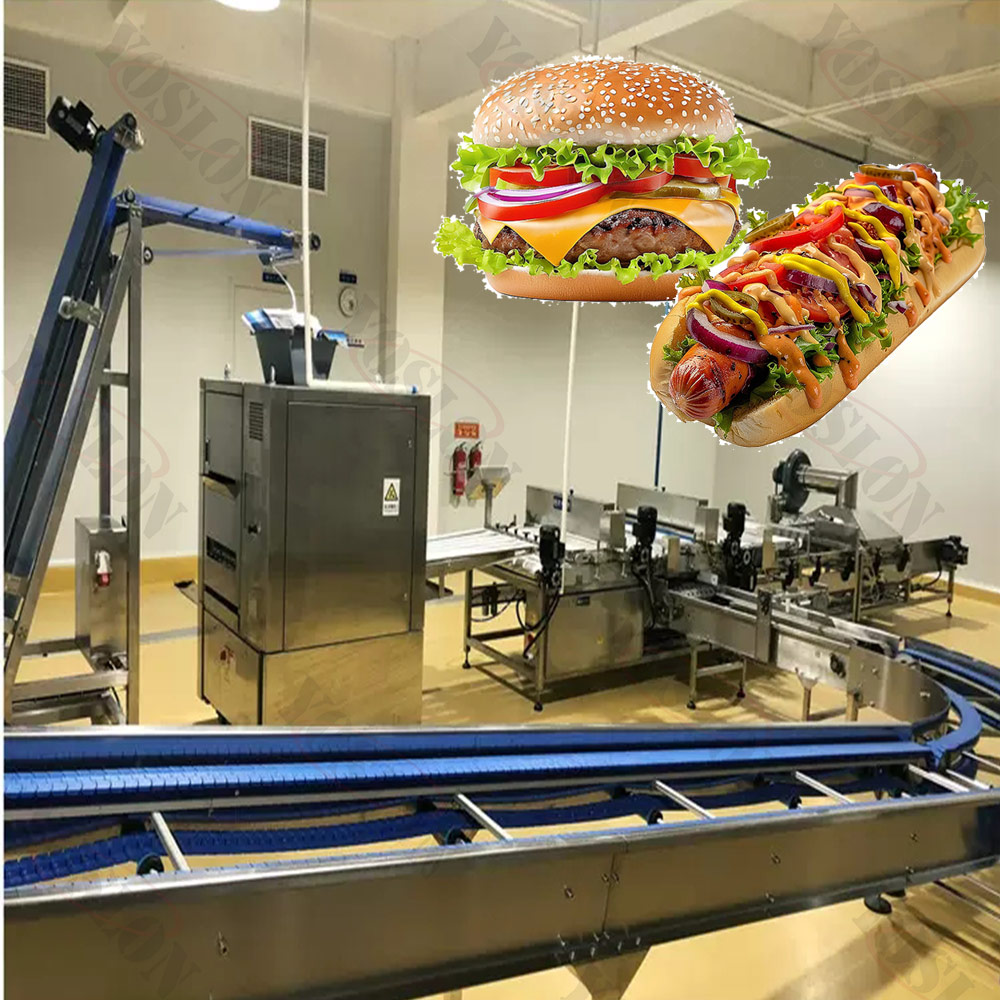

The production line has strong adaptability and wide application. It produces a wide variety of products (it can cut triangles, hexagons, strips, circles, rings, and complex patterns), and can easily and quickly replace cutters and optional programs.

Product Description

》》First Step:Dough Mixer

A Good Beginning Is Half The Battle: Our Dough Mixer Is Powerful, Double-Speed And Double-Action, Energy-Saving And Efficient To Knead The Dough Quickly. 》》Second Step:Dough Kneading Machine1.(Manual/ Automatic) double type kneading dough --- can set kneading times from 1 to 99 times 2.Adjustable the thickness of output sheet wheel from 8 to 18mm 3.Automatic flour dusters system --- can set the quantity of powder dusters 4.After finish kneading, It can be set automatically stop working time (0-30 seconds). 5.S-type continuous-folded extension of pressure, increased dough extensibility and gloss

》》Second Step:Dough Kneading Machine1.(Manual/ Automatic) double type kneading dough --- can set kneading times from 1 to 99 times 2.Adjustable the thickness of output sheet wheel from 8 to 18mm 3.Automatic flour dusters system --- can set the quantity of powder dusters 4.After finish kneading, It can be set automatically stop working time (0-30 seconds). 5.S-type continuous-folded extension of pressure, increased dough extensibility and gloss 》》Third Step:Baguette Dough Moulder1. Stainless steel body 2. PLC control 3. The output per is 20-180pcs per min 4. The machine has pulley, easy to move》》Fourth Step:Filling Machine

》》Third Step:Baguette Dough Moulder1. Stainless steel body 2. PLC control 3. The output per is 20-180pcs per min 4. The machine has pulley, easy to move》》Fourth Step:Filling Machine 1.Adopt servo system to control screw feeding, photoelectric sensor technology;

1.Adopt servo system to control screw feeding, photoelectric sensor technology;

2.Transparent silo design, easy to observe the material level;

3.Stainless steel structure, stable structure, removable and easy to clean and maintain;

4.Using world famous electronic components, reliable quality;

5.The interface can store the production parameter formula, which is convenient to use;

7.The screw can be replaced, the accuracy and efficiency can be taken into account;

7.Intelligent induction positioning and blanking without filling without tank;

8.All system control software can be adjusted and upgraded in future;

9.Can be used with a variety of automatic packaging equipment, convenient connection;

》》Fifth Step:Dough Divider

Divide The Dough Evenly According To The Weight You Want. Our Dough Divider Can Cut Out The Dough According To Your Own Weight Requirements, With Uniform Weight, High Efficiency And Energy Saving. 》》Sixth Step:Automatic Arranging MachineFully Automatic Arranging Machine, Fully Automatic Platting, Save Time And Effort, And Be More Organized.

》》Sixth Step:Automatic Arranging MachineFully Automatic Arranging Machine, Fully Automatic Platting, Save Time And Effort, And Be More Organized.

》》Seventh Step:Dough ProoferPut The Dough In The Refrigerated Proofing Box For Fermentation At The Most Suitable Temperature And Humidity. We Have Proofing Boxes With Both Refrigeration And Freezing Functions. If You Use The Freezer Proofing Boxes, You Don'T

》》Seventh Step:Dough ProoferPut The Dough In The Refrigerated Proofing Box For Fermentation At The Most Suitable Temperature And Humidity. We Have Proofing Boxes With Both Refrigeration And Freezing Functions. If You Use The Freezer Proofing Boxes, You Don'T

Need To Spend Extra Money To Buy A Freezer.

Our Machines Can Also Be Intelligently Timed, And You Don'T Have To Worry About Getting Up Early Or Missing The

Time.

》》Eighth Step:Put The Dough In The Oven For Baking

Our Oven Types Are Deck Oven And Rotary Oven, Each With Its Own Convenience; Our Oven Heats Up Evenly, Quickly Rises Up, And The Temperature Is Accurate. 》》Finally, You Can Taste The Crispy And Delicious Bread

》》Finally, You Can Taste The Crispy And Delicious Bread

-