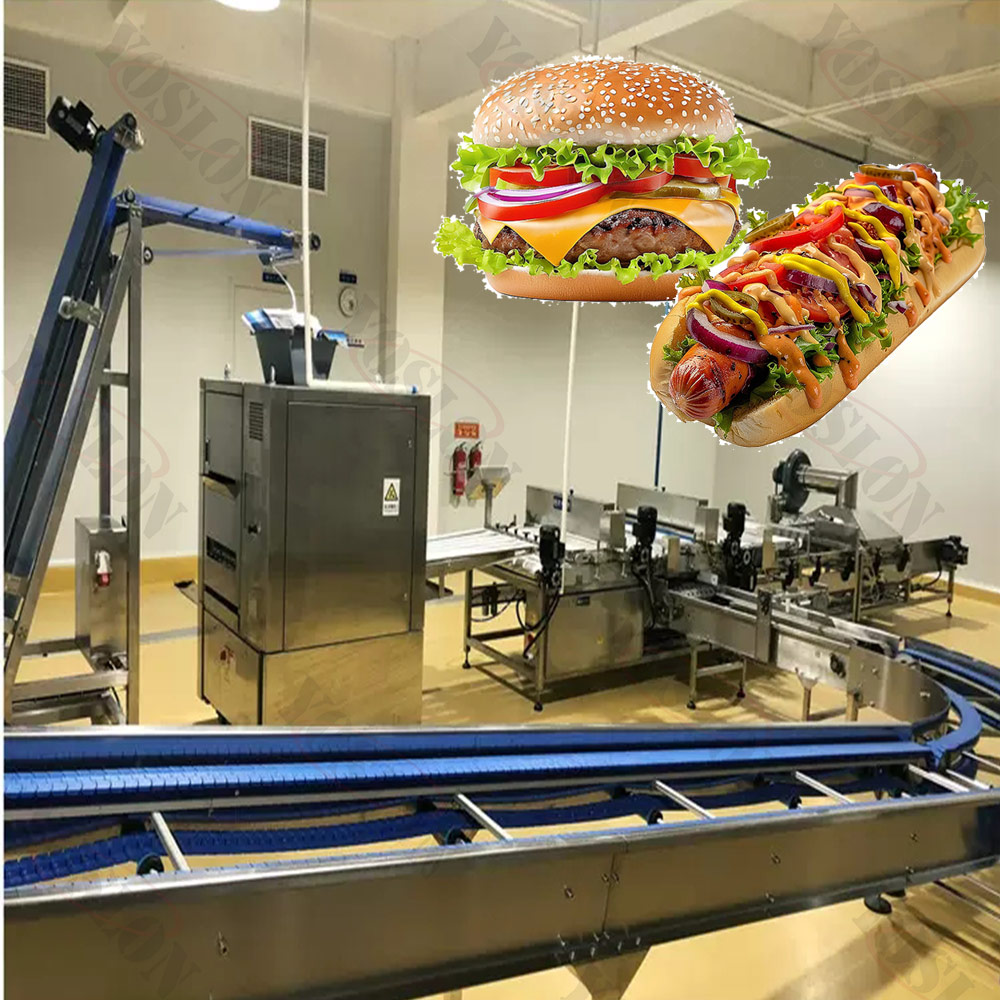

hotdog bread Forming Machine complete production line

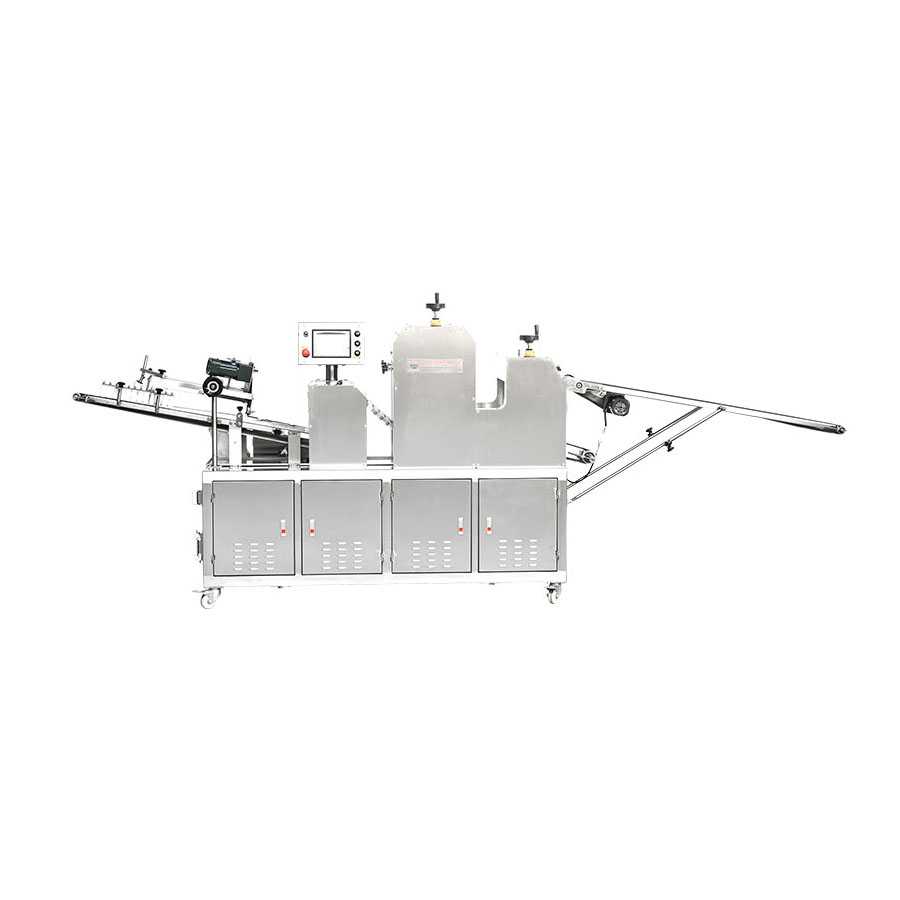

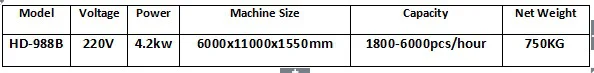

- Equipment

-

Product Description

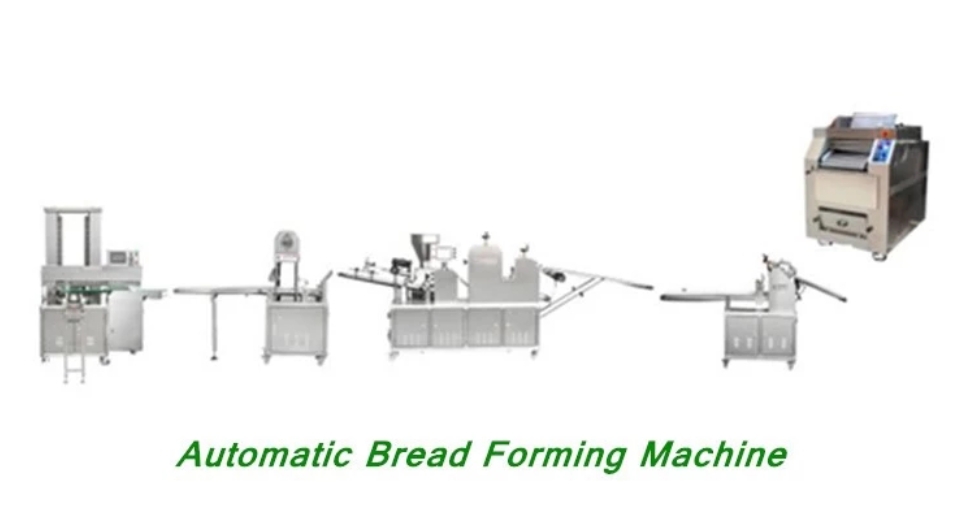

Hotdog bread Forming Machine complete production line

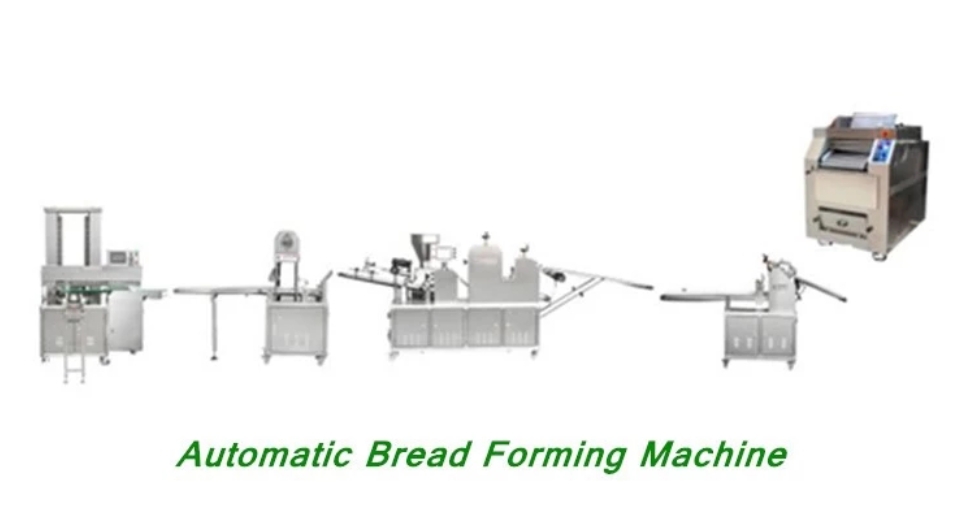

Automatic Bread Forming/ production line.

Production Characterristics:

1.This production line is made up of Mixer Machine, Continuous pressing machine, Dough cutter, Bread forming machine,.Main parts of machine are made of stainless steal, and food standard plastic,complying with health standards,welded by laser,stable,solid,durable and lasting.

2.Imported high speed motor cuts bread with alloy steel blade. Motors,Inverters and Electronic Components Adopt Chinese (TAIWAN, Japan Mitsubishi control system) Top Brand.

3.To have more stability and effectiveness and a higher degree of automation,we adopt Mitsubishi control syetem,double-servo and imported Germany SICK photo-electricity.

4.Capacity: 1800-6000PCS/HR for item one bread.

5.Machine designed more reasonable,easy to operate and every parts can be operated separately.

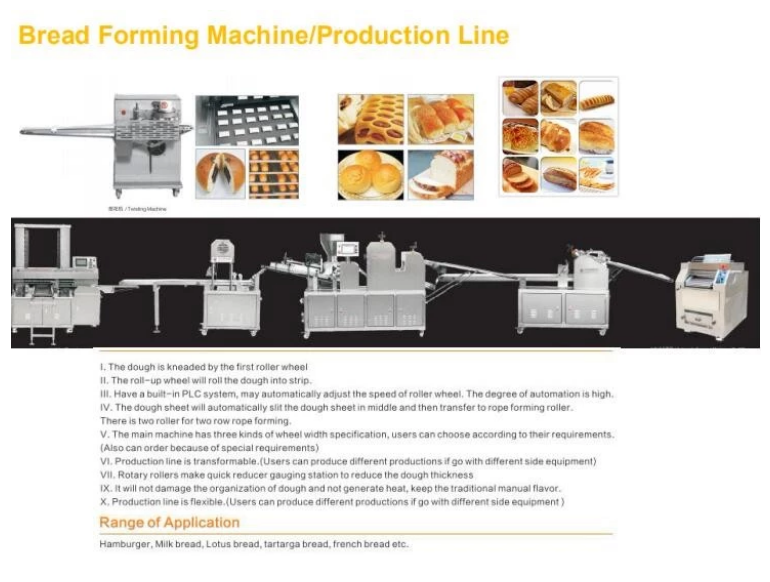

Range of application: Bread sandwich,hamburger,bun,rolls,long bread ,loaf, toast bread and sandwich,biscuit sandwich etc.

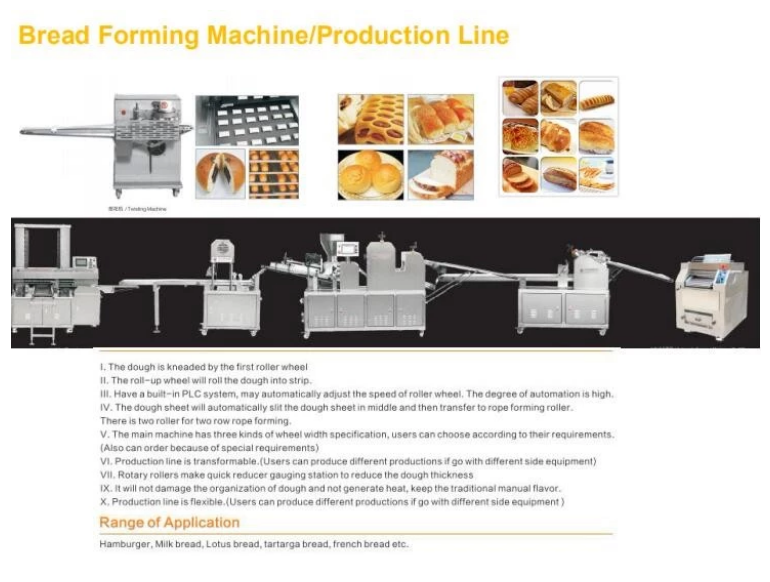

Products Showcasing

Related Products

1.Automatic Row Rope Forming Machine:

The dough is kneaded by the first roller wheel, when you can adjust the thickness of the dough, and rolled by rotary rollers made of twelve roller wheels and a roller wheel by the way of flapping bit by bit to rotary rollers made of twelve roller wheels and a roller wheel by the way of flapping bit by bit to make the dough more polish, weight and quality are stable. Then kneaded by shapely wheel which can adjust the thickness of the dough, according to the customer's requirements.

The roll-up wheel will roll the dough into strip.

Have a built-in PLC system, may automatically adjust the speed of roller wheel. The degree of automation is high.

The dough sheet will automatically slit the dough sheet in middle and then transfer to rope forming roller. There is two roller for two row rope forming.

The main machine has three kinds of wheel width specification, users can choose according to their requirements.(Also can order because of special requirements)

Production line is transformable.(Users can produce different productions if go with different side equipment)

Rotary rollers make quick reducer gauging station to reduce the dough thickness by a maximum facto of 6:1(Depending on the dough type and quality)

Automatically sprinkling system cooperates with different dough.

The roller wheel is made from the specific food material made in Japan.

Aluminum machine parts are made from the specific food material made in Japan.

It will not damage the organization of dough and not generate heat, keep the traditional manual flavor.

Production line is flexible.(Users can produce different productions if go with different side equipments)2.Automatic Rope Cutting Machine:

Functions Explanation:

Users can set the length of cutting.

Adopting the designation of clutch running. The machine can run with a high speed to increase the capacity, and also keep nicety.

Users can order the specific mould according to the requirements

Safety guard to prevent operator from hurting.

3. Filling Machine

Functions Explanation:

Users can set the size of stuff.

Adopting the designation of clutch running. The machine can run with a high speed to increase the capacity, and also keep nicety.

Users can choose various stuff according to the requirements

-

-

Voltage220V(Customizable)

-